What is silica dust?

Silica dust (crystalline silica) is found in some stone, rock, sand, gravel and clay. The most common form is quartz. Silica dust can also be found in the following products:

- bricks

- tiles

- concrete

- some plastic material.

When these materials are worked on, silica is released as a fine dust known as respirable crystalline silica or silica dust.

Today, all States and Territories in Australia have work health and safety laws that explain duty of care for employers and workers’ responsibilities.

Silica dust and cancer

Silica dust is harmful when inhaled into your lungs. As it is 100 times smaller than a grain of sand, you can be breathing it in without knowing.

Exposure to silica dust can lead to the development of lung cancer, silicosis (an irreversible scarring and stiffening of the lungs), kidney disease and chronic obstructive pulmonary disease. It is estimated that 230 people develop lung cancer each year as a result of past exposure to silica dust at work. Not all exposed workers will develop cancer; cancer risk increases with long term or repeated high level exposure.

Work and exposure to silica dust

Approximately 587,000 Australian workers were exposed to silica dust in the workplace in 2011. It has been estimated that 5758 of these will develop a lung cancer over the course of their life as a result of that exposure. The occupations with the greatest exposure include:

- miners

- construction workers

- farmers

- engineers.

You may be exposed to silica dust if your work involves:

- breaking, crushing, grinding or milling material containing silica dust

- sand blasting or casting

- paving, surfacing or cement finishing

- bricklaying

- demolition work

- road construction

- stonemasonery

- mineral ore-treating processes

- manufacture of glass, ceramics, brick, concrete, tile, metals or machinery.

Air monitoring for silica dust

The mandatory limit for silica dust exposure in Australia is 0.1mg/m3 averaged over an eight hour day, although the ACGIH have recommended this be limited to 0.025mg/m3. However, there is no evidence to support a safe level of silica dust exposure. Work Health and Safety (WHS) Regulation 50 states air monitoring by an occupational hygienist must be conducted every 12-18 months if there is health safety risk or if there is potential of exseeing the exposure limit. However, air sampling on its own is not enough.

Health surveillance

WHS Regulations state that health monitoring must be provided to workers who are continually working with silica dust and there is a significant risk to the worker’s health.

Safe Work Australia’s crystalline silica health monitoring guide outlines how to monitor workers. It can help to detect loss in lung function before permanent damage. These should be done before job placement and at least every three years (yearly for high-risk jobs).

Effective controls

All Australian workplaces must follow work health and safety laws. These can vary between states and territories although the duty of care for employers and workers across Australia is similar.

- Employers are required to ensure the health and safety of their workers and others at their workplace.

- Employers have a duty to control the risks associated with work.

- Workers must take reasonable care of their own health and safety, must not negatively affect the health and safety of other people and follow any reasonable instruction and workplace health and safety policies.

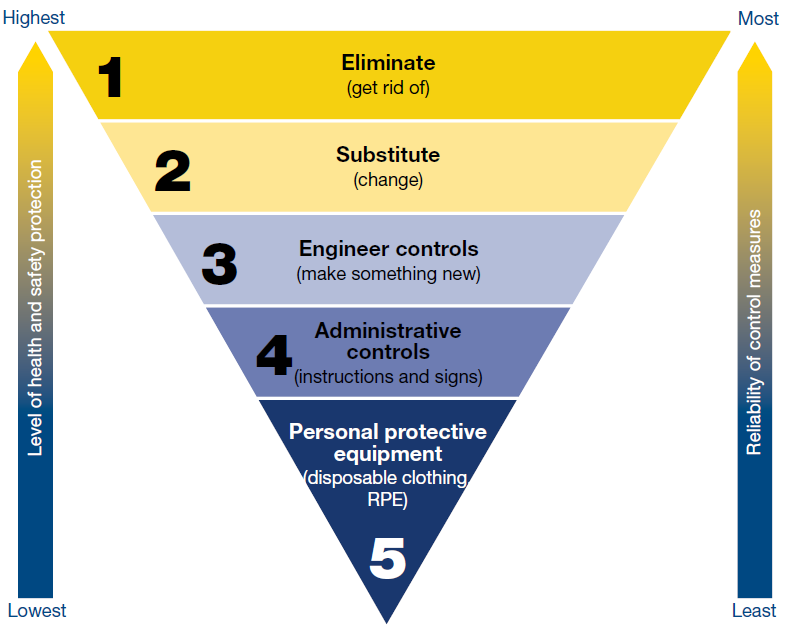

To follow work health and safety laws, employers should eliminate or reduce exposure to hazards by following the risk management process (figure 1). If suitable control measures are not in place, anyone working around silica dust has an increased risk of developing lung cancer. Workers should always be involved in the process.

How do I reduce my cancer risk?

If you are concerned about your health, or think you may have been exposed to a cancer causing agent, speak to your doctor.

The table below outlines a summary of control measures for silica dust.

| Table 1. Summary of control measures for silica dust | |

| ACTIVITY | CONTROL |

|---|---|

Construction, planning and design | For example, by:

|

Correct equipment |

|

Workshop ventilation | Have enclosures or hoods and local exhaust ventilation (LEV) to remove the dust at the point it’s produced. |

Abrasive blasting | WHS Regulations do not allow abrasives containing silica. Use metallic shot, slag products (ilmenite, garnet or staurolite) instead of sand. During blasting, containment methods such as blast-cleaning machines, cabinets and LEV should be used. |

On-tool extraction | Use LEV that fits directly onto the hand-held machines. This is the most effective way of controlling dust. |

Water suppression | To be used when LEV is not suitable. Water should be used through non-electric tools to wet dust down at the point of dust generation. For example, water should be provided to the blade when using saws; just wetting the material is not enough. Ensure equipment and work areas are cleaned regularly with water. Use water spray or rubber curtains around conveyor transfer points. |

Respiratory protective equipment (RPE) | No RPE can prevent all silica dust from being breathed in and should be used in combination with other controls. RPE cannot protect you if it doesn’t fit properly. Employers should have workers fit tested and trained in their use and maintenance. This is even more important if you have facial hair. It is important to choose the right RPE for the job; use the AS/NZS 1715:2009 standards or watch this HSE video for guidance on the selection and use of RPE. |

| Quit smoking | Smoking reduces the lung’s ability to clear dust and increases the risk of lung cancer. |

| PPE | If possible wear disposable clothing at work. Before you leave work, shower and change into clean clothes. Do not take your dusty clothes home to wash. |

| Administration | Display warning signs if tasks create silica dust. Rotate staff to limit the time they are exposed. Locate silica dust work outdoors, away from other workers. If not possible, enclose the area with floor to ceiling plastic sheeting. |

| Clean-up | DO NOT “clean up” with compressed air or by dry sweeping. Dust should be removed using an industrial HEPA (high-efficiency particulate air) filter vacuum, which should be cleaned and maintained regularly. |